Pelletizing

Pelletizing Solutions for Plastic Recycling: BOPP, CPP, PP Yarn, HDPE Films Recycling

Applications of Pelletizing Technology

Plastic materials, such as CPP yarn, PP yarn, PDPE film, and HDPE film, are transformed into small pellets or granular shapes through the processing of granulating extruders. These small pellets can be further used to manufacture new plastic products, achieving the reuse of plastic resources.

Benefits of Granulating Extrusion Technology

This granulating extrusion technology is widely applied in the plastic recycling industry, helping to:

- Increase the reuse rate of resources

- Reduce the demand for new raw materials

- Promote environmentally friendly and sustainable development of the plastic industry

Specialized Pelletizing Equipment

Chun Tai Machinery offers advanced equipment, including:

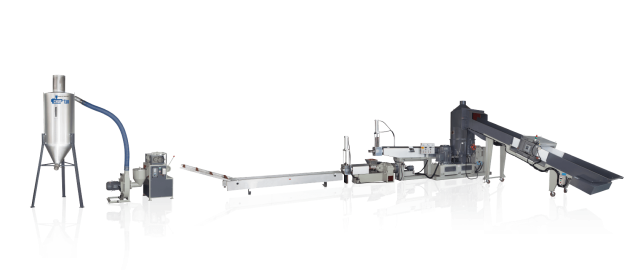

- 2 Stages Plastic Recycling Machine (Side Feeding): Designed for continuous feeding of bulky waste materials, providing efficient recycling solutions for large-scale operations.

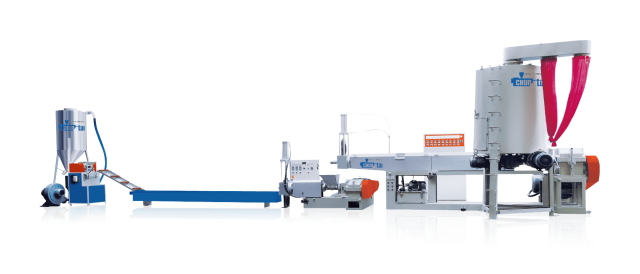

- 2 Stages Plastic Recycling Machine (Force Feeding): Features a force feeding system to handle lightweight and fluffy materials, ensuring consistent processing and high output quality.

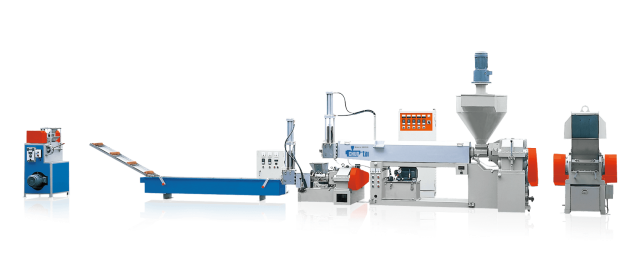

- 2 Stages Plastic Film Recycling Machine (Strand Cutting): Equipped with strand cutting technology, ideal for processing rigid and semi-rigid plastic waste into reusable pellets.

These machines ensure efficient processing and recycling of various plastic materials, meeting diverse industrial needs.

Innovative Recycling Features

All of Chun Tai Machinery's models are equipped with the function of online leftover material and formed leftover material recycling, which can be re-fed for processing. This innovation not only reduces the consumption of Earth's resources but also lowers production costs for customers.

Learn more about our Pelletizing Solutions and explore how our technology supports sustainable plastic recycling practices.