Plastic Flat Filament Manufacturing Machines: Principles, Features, Applications, and Trends

2024-06-20

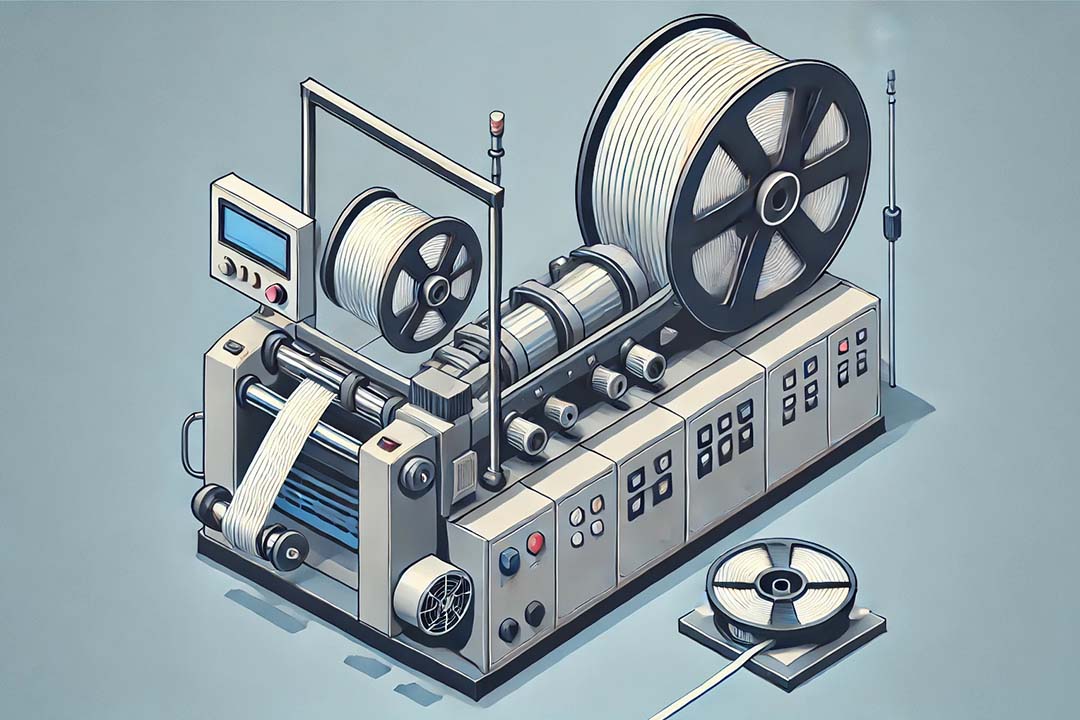

A flat filament manufacturing machines transforms plastic raw materials into flat yarn, which is widely used in various fields. The machine is designed to convert raw materials into flat yarns of various sizes and characteristics, making significant contributions to daily life, agriculture, and industrial products.

Working Principle of the Plastic Flat Yarn Making Machine

After the raw material is melted and plasticized in the plastic flat yarn making machine, it is extruded from the die head to form a film. The film is then rapidly cooled in a water tank, cut into strips after cooling, and heated by an arc-shaped plate. The heated plastic strips are then stretched in stages by rollers and undergo hot setting. After cooling, the flat yarn is wound into rolls.

Feed the plastic raw material pellets into the extruder hopper. The plastic pellets are heated and melted as they pass through the feed pipe. The molten plastic is extruded by the screw through the die to form a film. The plastic film is cooled and divided. The film is then heated and stretched into flat yarn by a traction machine. The flat yarn is shaped by a heat-setting machine. The flat yarn is wound into barrel-shaped spools.

- Feed the plastic raw material pellets into the extruder hopper.

- The plastic pellets are heated and melted as they pass through the feed pipe.

- The molten plastic is extruded by the screw through the die to form a film.

- The plastic film is cooled and divided.

- The film is then heated and stretched into flat yarn by a traction machine.

- The flat yarn is shaped by a heat-setting machine.

- The flat yarn is wound into barrel-shaped spools.

Main Features of the Plastic Flat Yarn Making Machine

- High Production Efficiency: The plastic flat yarn making machine adopts advanced design and technology, which can increase production efficiency and reduce production costs.

- High Quality: The plastic flat yarn making machine employs precise manufacturing processes to ensure the quality and stability of the flat yarn.

- Versatility: The plastic flat yarn making machine can produce flat yarns of various specifications and properties to meet different customer needs.

Applications of the Plastic Flat Yarn Making Machine

The plastic flat yarn produced by the plastic flat yarn making machine has a wide range of applications. It can meet the needs of various industries while promoting their development and innovation. The industries in which it is applied include:

- Packaging: The strength and versatility of plastic flat yarn make it an ideal choice for packaging applications. It is commonly used in the production of woven bags, sacks, and other packaging materials.

- Geotextiles: In civil engineering, plastic flat yarn is used in geotextiles for soil stabilization, erosion control, and reinforcement.

- Agriculture: Plastic flat yarn can be used to produce agricultural woven bags, films, and ropes. These products are used for harvesting and storing crops, providing protection, and offering structural support needed for crop growth.

- Construction: In the construction industry, plastic flat yarn can be used to produce construction meshes, insulation barriers, and waterproof materials. These products can enhance the strength and durability of building structures while providing thermal insulation and waterproofing functions.

- Automotive Industry: In the automotive manufacturing process, plastic flat yarn can be used to produce interior trims, interior linings, and woven materials for car seats. These products offer excellent wear resistance and comfort, enhancing the aesthetics and comfort of a car's interior.

- Environmental Industry: Plastic flat yarn can be used to produce eco-friendly bags, ropes, and other green products. These products can replace traditional plastic items, reducing environmental impact and promoting the development of the environmental industry.

Future Trends of the Plastic Flat Yarn Making Machine

With the continuous advancement of technology, the future trends of plastic flat yarn making machines may include:

- Intelligent Automation: Plastic flat yarn making machines will become more intelligent, capable of automatically adjusting parameters and controlling the production process.

- Energy Efficiency: Plastic flat yarn making machines will become more energy-efficient, reducing energy consumption and production costs.

- Customization: Plastic flat yarn making machines will become more customizable, capable of meeting the individual needs of different customers.

Plastic flat yarn making machines are essential equipment in modern industry. They provide crucial materials for industries such as textiles, packaging, and geotextiles, making significant contributions to their development. With continuous technological advancements, plastic flat yarn making machines will continue to evolve and improve, offering more and better products and services to human society.

All models from CHUNTAI are equipped with online scrap and formed scrap recycling functions, allowing for reprocessing. This not only helps reduce the consumption of Earth's resources but also lowers production costs for our customers. For more information, please feel free to contact us.