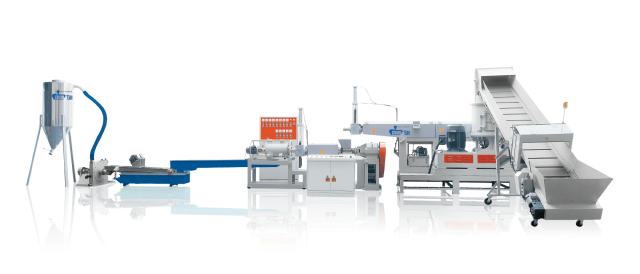

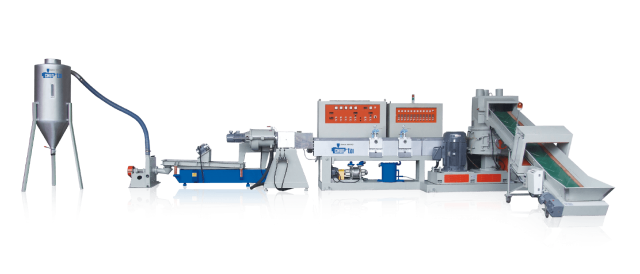

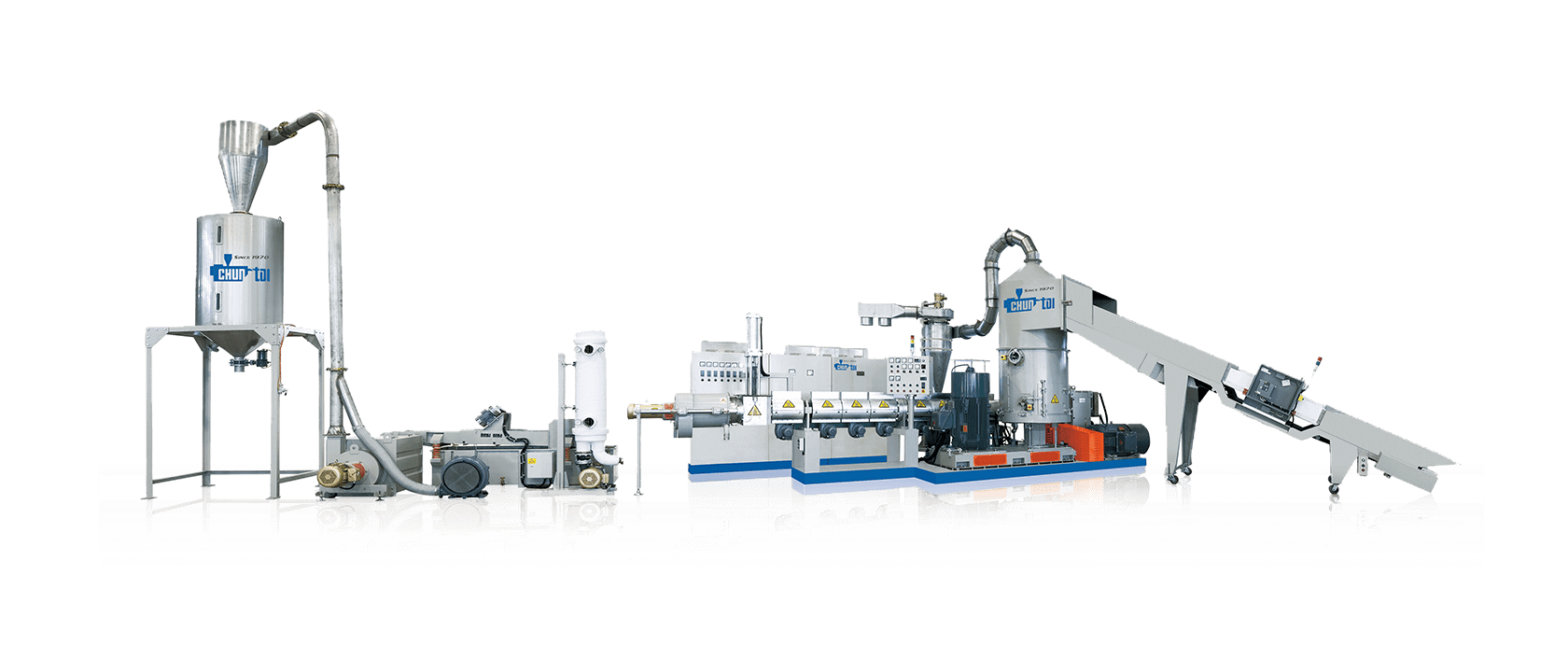

Plastic Film Recycling Machine (Die-face Cutting)

Product Overview

The Plastic Film Recycling Machine (Die-Face Cutting Type) is a high-efficiency system designed for recycling various types of film waste. It is suitable for processing plastic films, sheets, and related scraps, converting them into high-quality plastic pellets for reuse. Its integrated structure helps reduce manual labor, tool wear, and noise, while improving overall production efficiency—making it a practical solution for sustainable plastic manufacturing.

Key Features

- High-Efficiency Recycling:

Uses advanced single screw extrusion technology to recycle plastic films efficiently and produce high-quality recycled pellets. - Energy Saving and Environmental Compliance:

Designed to reduce blade wear, lower reliance on manual labor, and decrease noise output. Complies with environmental standards and supports plastic waste reduction. - Easy Operation:

Equipped with intuitive controls that are easy to operate, requiring minimal manual intervention. - Wide Material Compatibility:

Capable of processing various film materials such as PE, PP, and PS. Suitable for different types of film recycling applications.

This three-in-one machine offers reliable performance and supports sustainability by improving material reuse and reducing environmental impact.

Applicable Industries

- Blown Film Manufacturing: Handles edge trims, film waste, and production rejects to improve yield and reduce material loss.

- Sheet Reprocessing: Reprocesses reclaimed sheets for reuse in construction, packaging, and other plastic product applications.

- Plastic Products and Toy Manufacturing: Provides a stable output of recycled pellets for high-volume production.

- Recycled Plastics Industry: Produces quality recycled pellets through integrated recycling and pelletizing processes to support circular economy practices.

Technical Specifications

| Item | Specification |

|---|---|

| Applicable Materials | HDPE, LDPE, LLDPE, BOPP; suitable for mono- and multi-layer plastic films |

| Capacity Range | Approx. 100–1500 kg/hr |

| Extruder Type | Single screw extruder |

| Pelletizing Options | Die-face hot cutting and strand pelletizing supported |

| Feeding System | Compatible with automatic feeding systems (configuration based on material type) |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 12m × 5m × 3m |

Frequently Asked Questions (FAQ)

- Q1: What types of plastic materials can this machine recycle?

A: It can process HDPE, LDPE, LLDPE, and BOPP films, including both mono-layer and multi-layer types. - Q2: Does the machine require an external crusher for film waste?

A: No. The machine can process materials directly without a separate crusher. - Q3: What’s the difference between die-face cutting and strand pelletizing?

A: The choice depends on the material characteristics. Please contact our technical team for further guidance. - Q4: Can the machine handle printed or adhesive-coated films?

A: Yes, it can. - Q5: Can this machine be integrated into a fully automated production line?

A: This model is designed for stand-alone use and is not configured for full-line automation.

Related Products