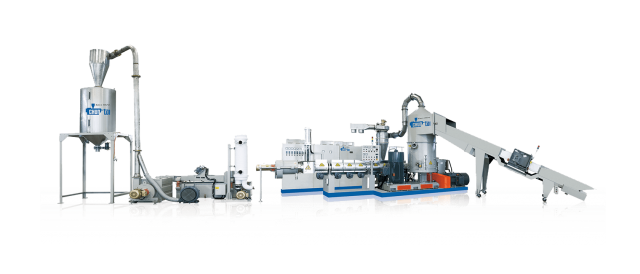

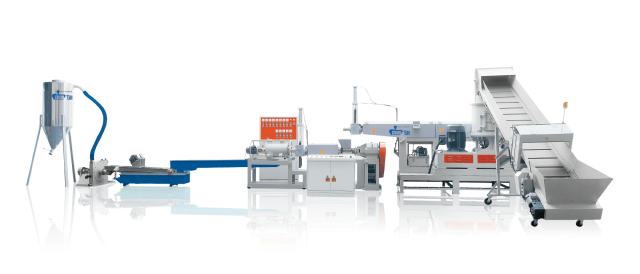

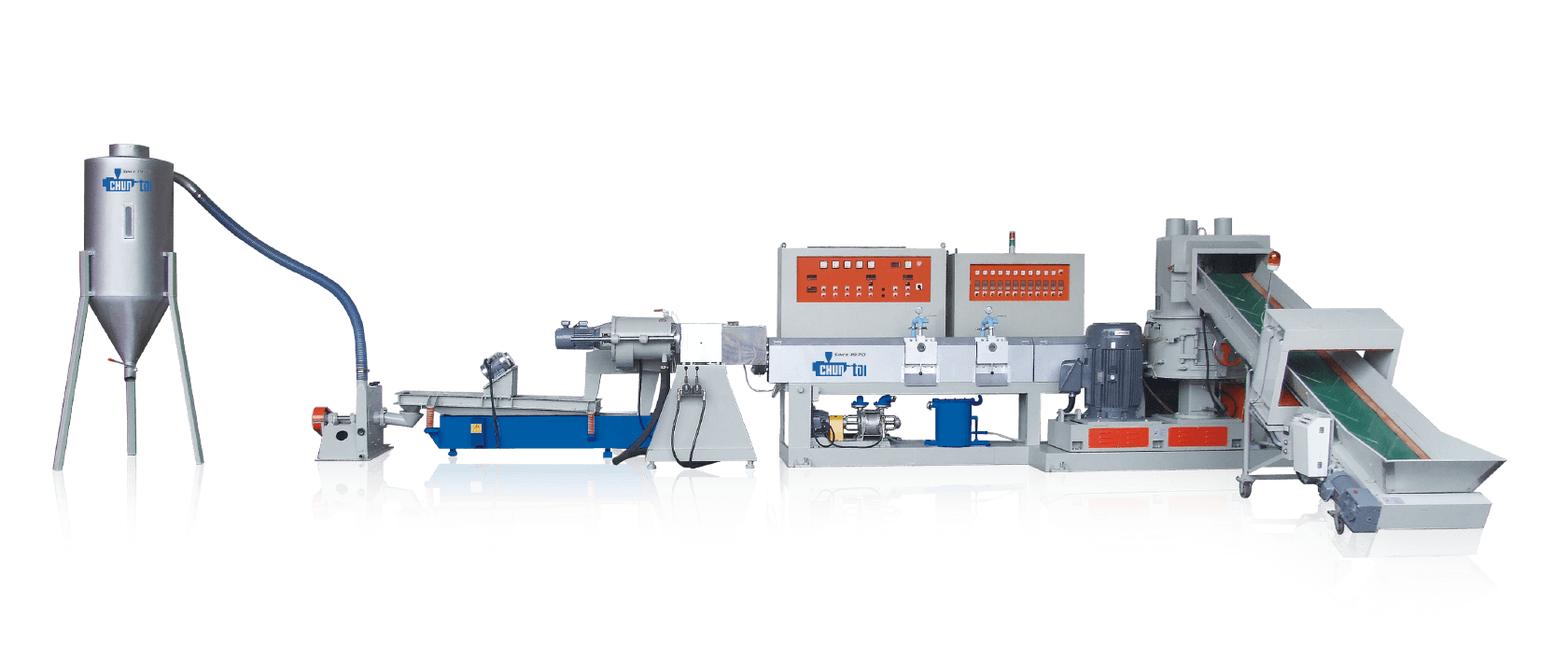

Single Screw Plastic Film Recycling Machine

Product Overview

The Single Screw Plastic Film Recycling Machine is purpose-built for processing film-type plastic waste such as PE, BOPP, agricultural films, and printed films. Designed for clean or pre-washed input, this compact 3-in-1 unit integrates shredding, single-screw extrusion, and die-face cutting to deliver stable performance and space-saving efficiency—ideal for medium- to high-output operations. Its die-face pelletizing system replaces traditional strand cutting and water tank cooling, simplifying operation while reducing labor and maintenance. To further enhance processing efficiency and safety, optional modules such as vacuum pumps, metal detectors, and temperature-controlled water-cooling systems are available.

Key Features

- Compact 3-in-1 Integrated System: Combines shredding, extrusion, and pelletizing into a single compact unit, minimizing space usage and operational complexity.

- Customizable Single-Screw Extrusion: L/D ratio and screw configuration can be tailored to match material types and processing requirements.

- Die-Face Cutting System: Replaces strand cutting and water tanks, reducing floor space needs and eliminating water handling.

- Quick Changeover Capability: Fast-switch cutter and die design minimizes downtime and improves production flexibility.

- Integrated Drying, Preheating & Compounding: Ensures consistent pellet quality and enhances processing stability, even for moisture- or ink-contaminated materials.

- Optional Modular Enhancements: Supports integration with vacuum pumps (for degassing), metal detectors (for equipment protection), and water-cooling units (for process temperature control).

- Temperature-Controlled Water Cooling: Delivers efficient and stable cooling for downstream pelletizing, even under high throughput.

- Full-Line Integration Support: Compatible with upstream washing lines and automatic feeding systems to support complete recycling workflows.

Applications

- Recycling of film-type plastics such as PE, BOPP, agricultural films, and printed films

- Processing of washed materials with residual moisture or ink

- Pellet production for reuse in film blowing, injection molding, and profile extrusion

Technical Specifications

| Item | Specification |

|---|---|

| Recyclable Materials | PE, BOPP, agricultural films, printed films, and other film-type plastics |

| Material Condition | Supports clean or washed materials with residual moisture or ink |

| Extrusion System | Single-screw system with customizable L/D ratio and screw configuration |

| Screw Zones | Adjustable heating zones and pitch settings |

| Pelletizing Method | Die-face cutting (non-water strand); cold cutting not supported |

| Cooling System | Temperature-controlled water cooling |

| Degassing & Filtration | Dual degassing with quick-change screens (no automatic pressure detection) |

| Modular Add-Ons | Vacuum pump, metal detector, water cooling unit |

| Inline Integration | Supports optional integration with washing lines or automatic feeding systems |

| Output Capacity | Approx. 200–1500 kg/hr (varies by material condition and type) |

FAQ

- Q1: What types of plastic waste is this model designed to process?

A1: This machine is specifically optimized for film-type plastic waste such as PE, BOPP, agricultural films, and printed films. - Q2: Can it handle materials with moisture or ink contamination?

A2: Yes. The system includes preheating, degassing, and compounding functions to ensure stable processing of contaminated or high-moisture input. - Q3: What pelletizing method does it use, and how does it benefit the operation?

A3: The machine uses a die-face cutting system that eliminates the need for strand cutting and water troughs, reducing labor and saving space. - Q4: Is pellet size adjustable, and does the machine support quick changeovers?

A4: Yes. Pellet size is adjustable, and the cutter and die can be quickly changed to minimize downtime during product transitions. - Q5: Are dual degassing and filtration systems included? Is automatic pressure detection supported?

A5: Dual degassing and quick-change screens are included. However, automatic pressure monitoring is not supported in this model. - Q6: What optional modules are available and what are their purposes?

A6:- Vacuum Pump: Removes moisture and volatile impurities from input material

- Metal Detector: Prevents metal particles from damaging internal components

- Water Cooling System: Maintains consistent temperatures during high-output runs

- Q7: Can the system be integrated with other upstream equipment?

A7: Yes, the machine can be integrated with washing lines and automatic feeding systems to form a complete recycling line. - Q8: What is the typical throughput capacity? Is it affected by material quality?

A8: Output ranges from 200 to 1500 kg/hr, depending on the cleanliness, moisture, and contamination level of the input materials.