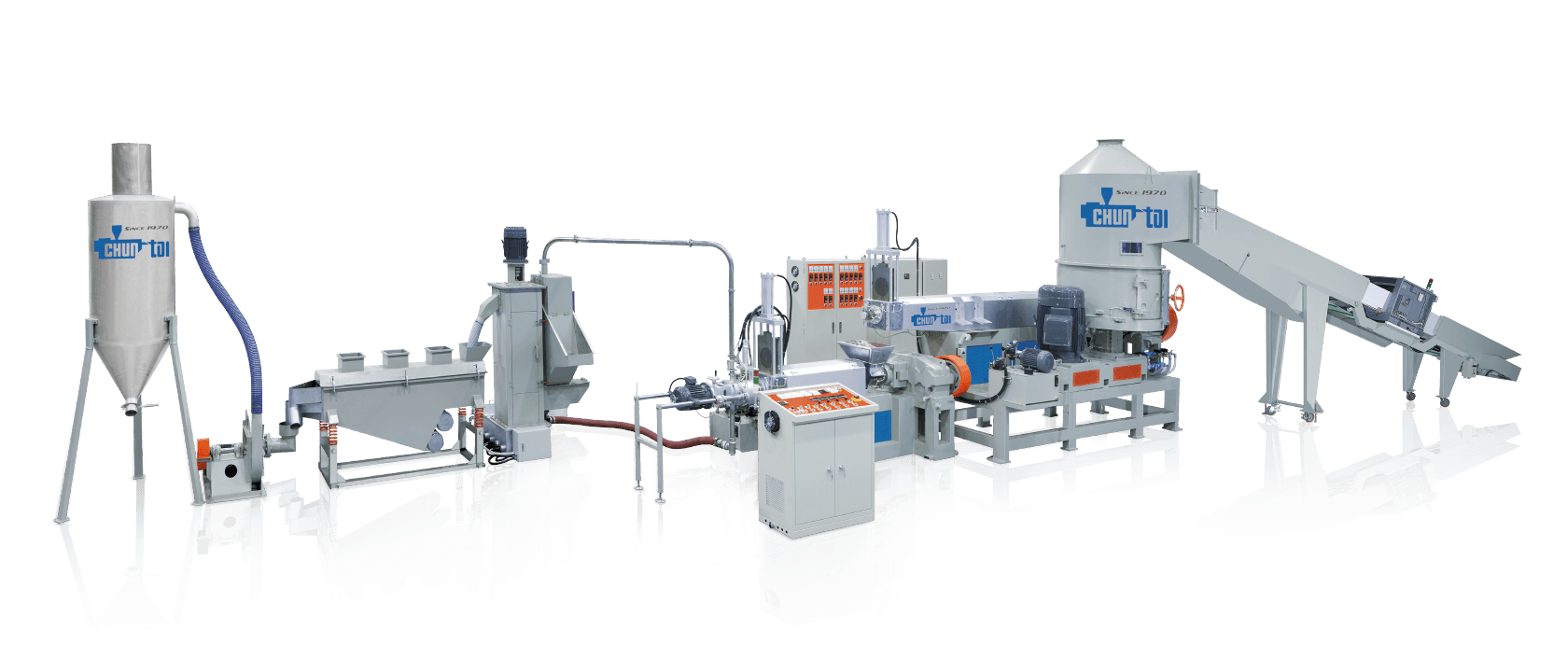

Underwater Pelletizer

Product Overview

The Underwater Pelletizer is purpose-built for processing materials such as PP, PU, PA, and other high melt index (MI) or engineering-grade thermoplastics and elastomers. It excels in applications involving heat-sensitive, high-viscosity, or easily degradable compounds. The process consists of four key stages: melt extrusion, die-face cutting, underwater cooling, and centrifugal drying. This configuration ensures precise pellet sizing, consistent shape, and excellent cooling efficiency—making it ideal for high-volume micro pellet production. Common applications include footwear materials, medical-grade elastomers, engineering plastics, and composite granules.

Key Features

- Optimized for High-MI and Heat-Sensitive Materials:

Handles PP, PU, PA, TPU, TPE, and other advanced thermoplastics with high processing requirements. - Auto-Compensating Cutter Head:

Features automatic pressure regulation, blade angle adjustment, and wear compensation to maintain consistent cutting quality. - Adjustable-Speed Rotary Cutter:

Supports blade speed and count adjustments to match different material viscosities and achieve uniform pellet size. - Closed-Loop Underwater Cooling System:

Fully recirculated cooling water system compatible with chillers or heat exchangers; minimizes water usage and environmental impact. - Integrated Centrifugal Dryer:

Removes water efficiently, delivering dry pellets directly without requiring additional drying—ideal for continuous, high-throughput production. - Automation-Ready Feeding Interface:

Supports connection to automated feeding modules for improved efficiency and production continuity.

Applications

- Micro Pellet Production:

High-output, fine-pellet manufacturing for technical and specialty applications. - High-Viscosity Material Processing:

Suitable for TPU, TPE, PA, PU, and other demanding elastomeric compounds. - Footwear, Medical, and Specialty Elastomers:

Used in the production of soft-touch, medical-grade, or impact-resistant polymer materials. - Engineering Plastics & Composite Granules:

Supports consistent pelletization where size uniformity and precision are critical.

Technical Specifications

| Item | Specification |

|---|---|

| Applicable Materials | PP, PU, PA, high MI plastics, heat-sensitive and high-viscosity compounds |

| Pelletizing Method | Underwater die-face cutting with automatic pressure, angle, and wear compensation |

| Cooling System | Closed-loop water cooling system; compatible with chillers or heat exchangers; recirculated water use |

| Dewatering Method | Integrated centrifugal dryer; no secondary drying required |

| Pellet Size Control | High consistency; supports micro pellet production |

| Cutter Head | Rotary cutter with adjustable speed and configurable blade count |

| Line Integration | Compatible with automated feeding modules; excludes quick-change die head, screening, and packaging units |