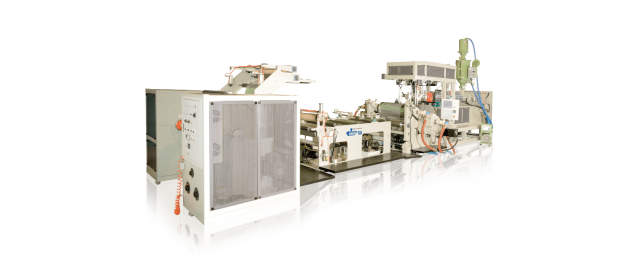

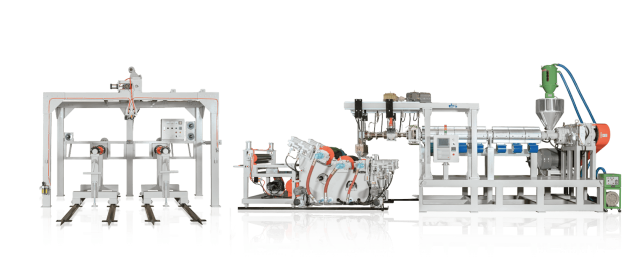

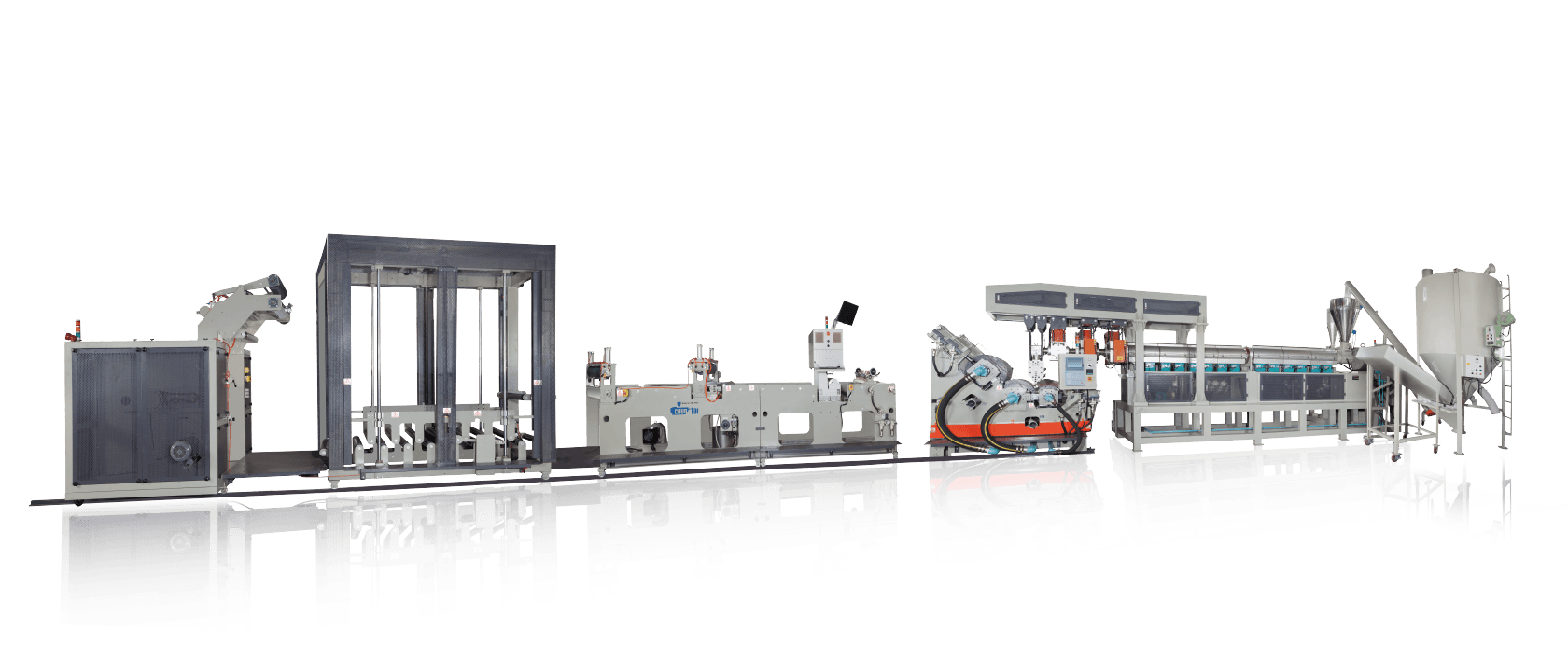

PP/HIPS Sheet Extruder

Product Introduction

Our PP/HIPS Sheet Extruder is specifically designed for producing polypropylene (PP) and high-impact polystyrene (HIPS) sheets, which are widely used in food packaging, medical device packaging, electronic product packaging, and other industries. This equipment offers high-efficiency and stable production capabilities, ensuring the quality and consistency of every batch of products. It is an ideal choice for producing various thermoforming sheets, catering to both small-scale customization and large-scale production needs, enhancing your production efficiency.

Technical Specifications

- Extrusion Capacity: Supports efficient extrusion to meet different scales of production requirements.

- Sheet Thickness: Capable of producing PP/HIPS sheets with thicknesses ranging from 0.2mm to 2.0mm to fulfill specific application needs.

- Extrusion Width: Maximum extrusion width of up to 1200mm, accommodating various wide-sheet production requirements based on customer needs.

- Control System: Equipped with an advanced PLC control system for precise temperature control and thickness adjustment, ensuring consistency and high quality in every batch of products.

- Performance: Features an energy-saving design with inverters and servo motors, reducing operating energy consumption and complying with environmental standards, contributing to green production.

- Machine Structure: Easy to maintain and upgrade, the machine can be flexibly configured based on production needs, ensuring production flexibility and stability.