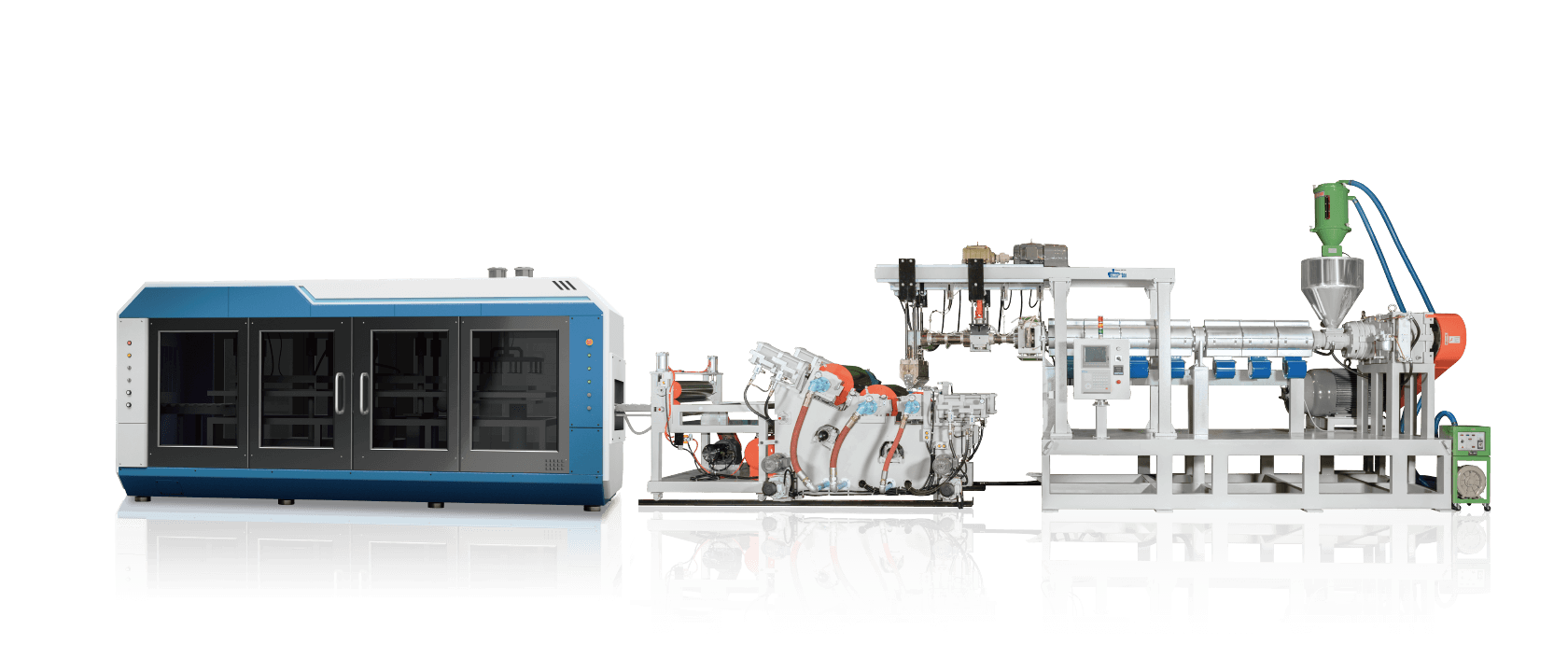

PP/PS Thermoforming Sheet Extruder

Product Introduction

Our PP/PS Thermoforming Sheet Extruder is designed specifically for producing high-quality polypropylene (PP) and polystyrene (PS) thermoforming sheets. This equipment is ideal for continuous, high-speed, mass production, serving various industries such as beverage cup forming, food box forming, and medical cup forming. It produces sheets with excellent performance and directly connects to the forming machine without the need for sheet rewinding, thereby reducing storage space and energy consumption from reheating.

The machine meets the high standards of the thermoforming product market, providing efficient and stable production solutions for both small-scale customization and large-scale production needs.

Technical Specifications

- Extrusion Capacity: Supports efficient extrusion to meet different scales of production requirements.

- Sheet Thickness: Capable of producing PP/PS sheets with thicknesses ranging from 0.2mm to 2.0mm to fulfill specific application needs.

- Extrusion Width: The extrusion width can be matched with the forming machine size, making it suitable for various wide-sheet forming machine production requirements.

- Control System: Equipped with an advanced PLC control system for precise temperature control and thickness adjustment, ensuring consistency and high quality in every batch of products.

- Performance: Features an energy-saving design with inverters and servo motors, reducing operating energy consumption and complying with environmental standards, contributing to green production.

- Machine Structure: Easy to maintain and upgrade, the machine can be flexibly configured based on production needs, ensuring production flexibility and stability.

Related Products